12 / 1 / 2026

Voxshell × Spherene: Enabling Scalable CAE Workflows for Advanced Thermal Systems

Introduction

As thermal and energy systems become more compact, efficient, and performance-driven, engineering teams face increasing pressure to evaluate complex geometries under tight design cycles. High-fidelity simulation is essential, but traditional CAE workflows often struggle to scale when geometry complexity and iteration speed increase.

Voxshell is working with Spherene to address this challenge by enabling robust, automated CAE workflows for lightweight structural design and novel heat exchanger development.

Challenge: Slow Preprocessing

Spherene’s technology involves advanced geometric features designed to maximise surface area, structural efficiency, and thermal performance. While these designs unlock significant performance benefits, they also present challenges for conventional CAE pipelines:

Geometry complexity makes manual meshing time-consuming

Repeated design iterations amplify preprocessing overhead

High-fidelity CFD and FEA require consistent, repeatable meshes

Traditional workflows do not scale well for parametric or AI-driven design exploration

In practice, this means that engineering insight is often delayed not by solver speed, but by preprocessing bottlenecks.

Automated CAE Infrastructure

Voxshell provides automated simulation infrastructure that prepares complex geometries for large-scale, parallel simulation with minimal manual effort. Within the Voxshell–Spherene collaboration, this capability supports two key workflows:

Lightweight Structural Analysis (FEA)

For structural performance and weight optimisation, Voxshell enables:

This allows Spherene’s engineers to evaluate structural performance earlier in the design process and explore a wider design space without manual remeshing. FEA analysis was done in nTOP for Case 1 and 2. Summarise the mesh file:

Automated generation of high-quality meshes for complex, thin-walled structures

Consistent preprocessing across design variants

Rapid iteration for stiffness, strength, and weight trade-offs

Case 1: 1.2 M Element, 664K Points

Case 2 : 9M Element, 5M Point

Case 3: 44M Element, 22 M Points

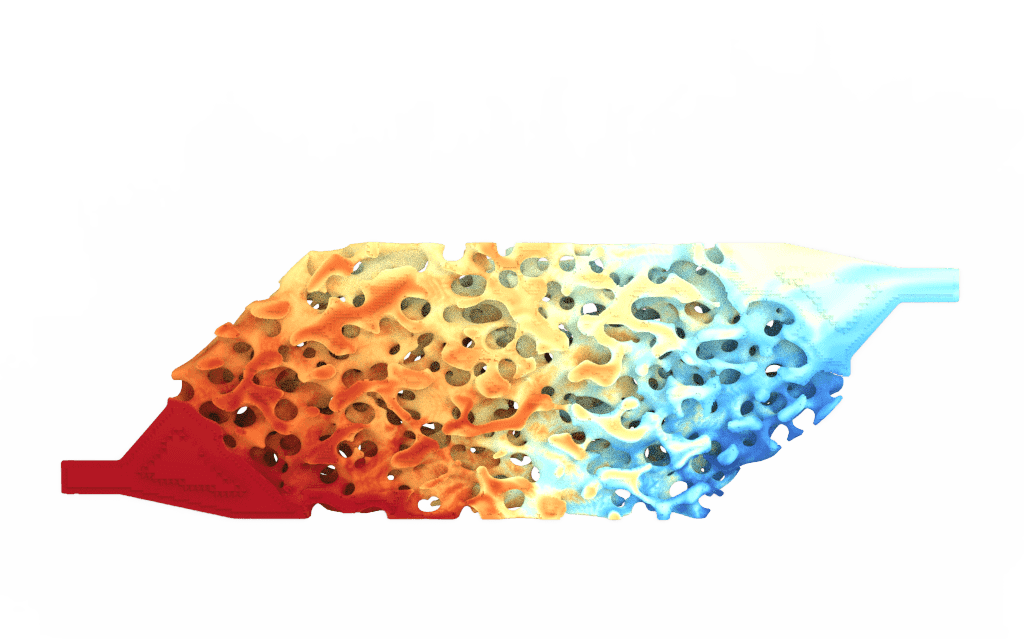

CFD for Novel Heat Exchanger Design

For thermal and fluid performance, Voxshell supports:

Robust meshing of complex internal flow passages

Repeatable CFD preprocessing across multiple configurations

Scalable batch workflows for parametric studies

The CFD Conjugate Heat Transfer mesh and setupfile files takes 5 mins:

Cold fluid: 7.0M elements

Hot fluid: 6.8M elements

Solid: 7.5M elements

By removing manual setup steps, Voxshell enables faster feedback on pressure drop, heat transfer, and flow uniformity, accelerating optimization of novel heat exchanger concepts

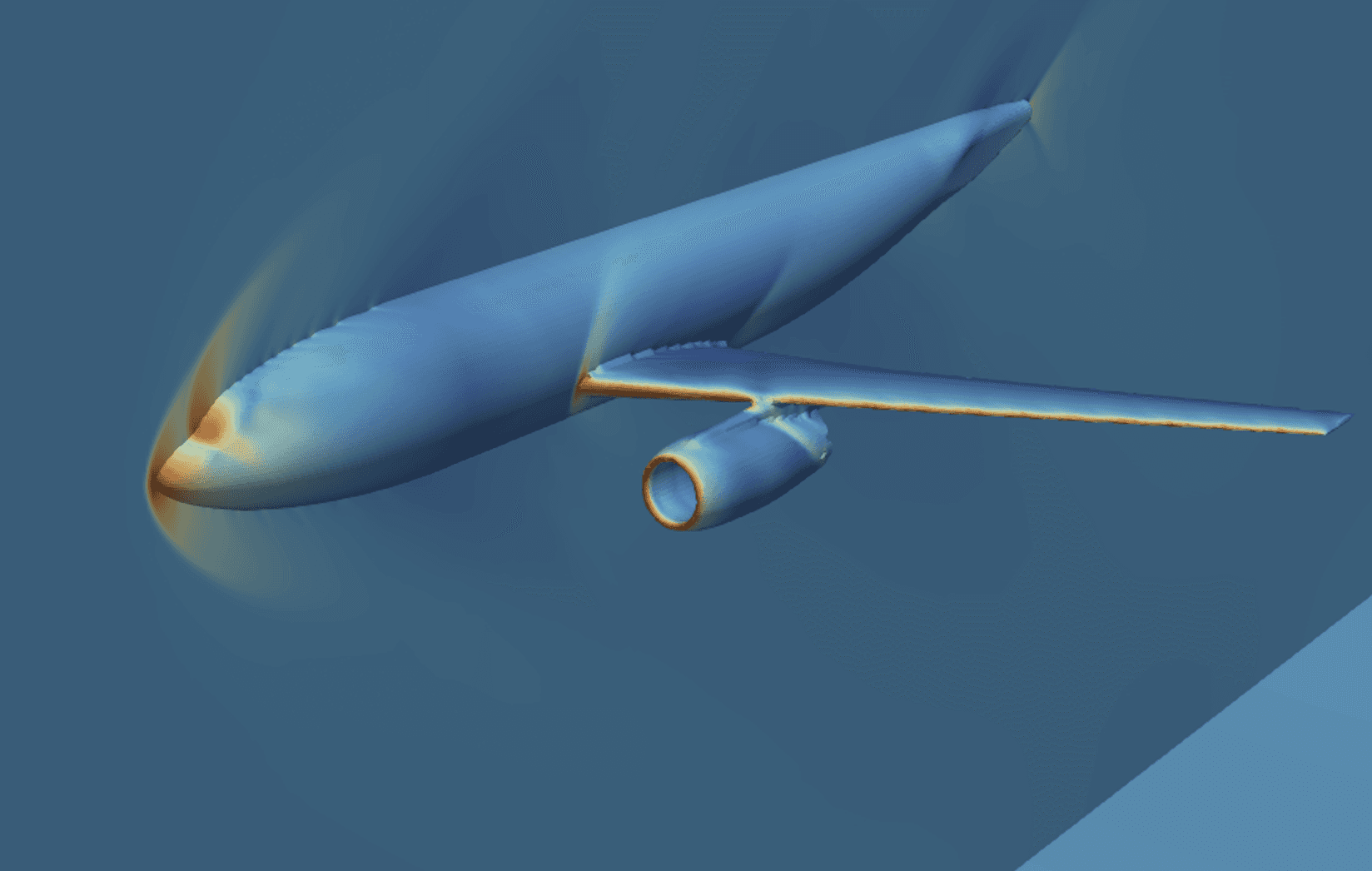

From Individual Simulations to Scalable Workflows

A key advantage of the Voxshell platform is its focus on workflow automation, rather than isolated simulations. This means:

Deterministic, repeatable preprocessing pipelines

Reduced human error in mesh generation

Support for large-scale parametric studies

AI-ready data generation for future optimisation workflows

This approach shifts CAE from a manual, case-by-case activity to infrastructure that scales with design ambition.

Engineering Impact

By integrating Voxshell’s automated CAE workflows into its development process, Spherene can:

Run more simulations earlier in the design cycle

Make better-informed design decisions with higher confidence

Accelerate the development of high-performance, energy-efficient thermal systems

The result is not only faster engineering, but better engineering outcomes—with lower cost, less rework, and improved design quality.

Look Ahead

The Voxshell–Spherene collaboration demonstrates how modern CAE infrastructure can unlock the full potential of advanced geometry and novel thermal concepts. As engineering teams increasingly adopt AI-driven and data-intensive design methods, automated and scalable simulation workflows will become a foundational capability.

Voxshell is proud to support Spherene in advancing next-generation thermal and structural engineering through robust, production-ready CAE workflows.